-

The demand for PE is declining and demand for PP is growing steadily07 01,2022

The demand for PE is declining and demand for PP is growing steadily07 01,2022Limited by the impact of plastic order, the growth rate of domestic PE demand will decline. In the next few years, there will still be a large number of new proposed projects, facing the pressure of structural surplus. It is estimated that in 2022, China's PP production capacity will increase by 5.15 million tons / year to 37.31 million tons / year. The main consumption of plastic woven products has been surplus, but the demand for PP of injection molded products such as small household appliances, daily necessities, toys, automobiles, food and medical packaging materials will grow steadily, and the overall supply and demand balance will be maintained.

-

China's PP export volume fell sharply in the first quarter!06 30,2022

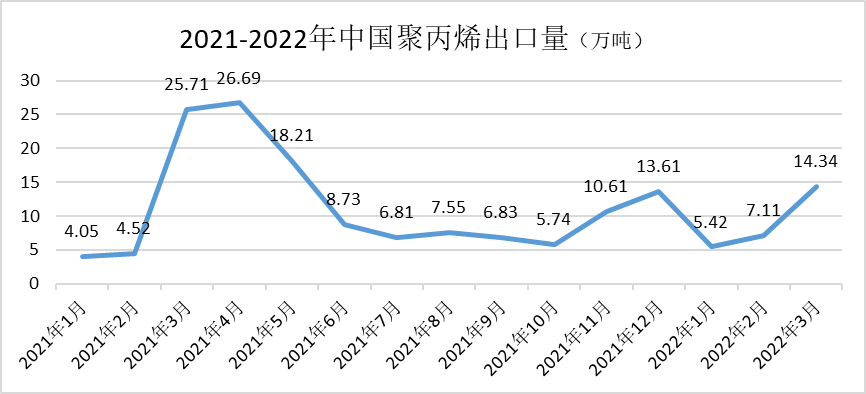

China's PP export volume fell sharply in the first quarter!06 30,2022In the first quarter of last year, the extreme cold and epidemic situation in the United States led to the tightening of polypropylene supply in the United States and Europe. There was a demand gap overseas, resulting in relatively large exports. At the beginning of this year, geopolitical factors combined with tight supply and demand of crude oil led to high oil prices, high costs for upstream enterprises, and domestic polypropylene prices were dragged down by weak domestic fundamentals. The export window continued to open. However, due to the earlier release of epidemic prevention and control overseas, the manufacturing industry returned to the state of high opening rate, resulting in a serious year-on-year decline in China's export volume in the first quarter.

-

The 42 billion large project started this month! This Chinese province is buildi06 14,2022

The 42 billion large project started this month! This Chinese province is buildi06 14,2022Since the "Petrochemical Industry Planning and Layout Plan" formulated by the National Development and Reform Commission put forward the construction of seven world-class petrochemical bases, many large-scale petrochemical projects in China have been continuously promoted, and each petrochemical base has accelerated the progress of the layout. The official launch of the Zhongsha Gulei ethylene project will promote the development of the Gulei petrochemical industry and bring the Gulei petrochemical base to a new level. The Zhongsha Gulei project is expected to build 1.5 million tons of ethylene plant, 600,000 tons of mLLDPE/HDPE plant, 400,000 tons of HDPE (twin peak) plant, 400,000 tons of polypropylene (impact) plant and 550,000 tons of polypropylene (homopolymer) /random) device. In the past two decades, the petrochemical industry has always been the leading industry that Fujian has focused on fostering, and now this industry has become one of the three leading industries in Fujian Province. Due to the high degree of industrial correlation, long industrial chain and wide product coverage, it has played an important supporting role in Fujian's economic development. The launch of this project will further enhance the strength of Fujian's petrochemical industry, and is also an important practice for Fujian Province to successfully introduce major foreign investment projects. At the same time, with the establishment of Saudi Basic Industries Corporation, a leader in the global chemical industry, Gulei will make full use of this decade to form an internationally competitive petrochemical industry system. This is of great significance to promoting the high-quality development of my country's petrochemical industry, improving the supply capacity of domestic high-end chemicals, and promoting the construction of the Gulei petrochemical base into a world-class petrochemical industry base. The seven major petrochemical bases in China are Shanghai Caojing, Zhejiang Ningbo, Guangdong Huizhou, Fujian Gulei, Dalian Changxing Island, Hebei Caofeidian, Jiangsu Lianyungang, and many projects are continuing to advance, and each petrochemical base is accelerating the progress of the layout. International giants have also seized the dividends of opening up and landed in the Chinese refining and chemical market. ExxonMobil, BASF and other wholly foreign-owned petrochemical projects are advancing in an orderly manner. Shell and Saudi Aramco will also cooperate with domestic petrochemical companies in the refining and chemical field. It is estimated that by 2025, the refining capacity of the seven petrochemical bases will account for 40% of the country's total capacity. At present, China has built and put into operation nearly 30 10 million-ton oil refining bases, with a total production capacity accounting for about 45% of China's total oil refining capacity. China's refining and chemical industry is developing in the direction of large-scale installations, refining and chemical integration, and industrial clustering, and is entering an era of great changes in competition and diversification. With the integration and upgrading of the petrochemical industry, it is believed that a new pattern will be formed in the near future.

-

For the first time! CNPC Guangxi exports polypropylene L5E89 to Vietnam04 18,2022

For the first time! CNPC Guangxi exports polypropylene L5E89 to Vietnam04 18,2022On the morning of March 25, 2022 , for the first time, 150 tons of polypropylene products produced by CNPC Guangxi Petrochemical Company sailed to Vietnam via container on the ASEAN China-Vietnam freight train, marking that CNPC Guangxi Petrochemical Company's polypropylene products opened a new foreign trade channel to ASEAN and laid a foundation for expanding the overseas market of polypropylene in the future. CNPC Guangxi Petrochemical Company's polypropylene resin L5E89 belongs to the general material product, widely used in the manufacture of woven bags and disposable plastic cups and other purposes, having a good reputation in the domestic market, widely liked by customers, with good economic benefits. (It is reported that many trading companies, such as Shanghai Chemdo, also export L5E89 polypropylene in large quantities to Pakistan, India and other international markets.) Under the severe situation of epidemic prevention and control, the production and technical personnel of CNPC Guangxi Petrochemical Company overcame difficulties and formulated detailed production plans, continuously optimized key production parameters, controlled load and stabilized production, realized low ash content of products, and ensured green products. The export of polypropylene to Vietnam through the ASEAN China-Vietnam freight train is a successful exploration of CNPC Guangxi Petrochemical Company to seize the market opportunity, cooperate with GUANGXI CNPC International Enterprise Company, South China Chemical Sales Company and Guangxi CoSCO Overseas Transportation Company, give full play to the overall advantages of production, sales, trade and transportation, and expand the overseas market. Which not only opens a new channel for CNPC Guangxi Petrochemical Company to export polypropylene products, but also is the quality recognition for CNPC Guangxi Petrochemical Company's polypropylene products in overseas markets.